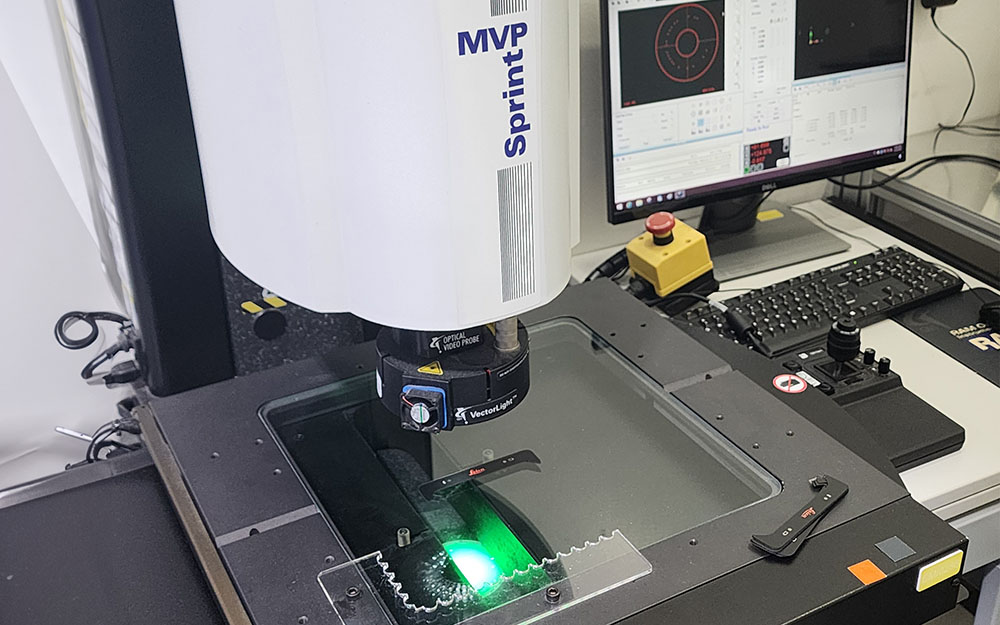

High Precision 3D Measuring

Accurate Dimensional Measurement: High-precision 3D measuring provides accurate measurements of complex geometries and intricate surfaces. This is crucial in manufacturing, quality control, and engineering to ensure products meet design specifications.

Quality Control: Industries such as aerospace, automotive, and medical manufacturing rely on high-precision 3D measuring for quality control. It allows for the detection of deviations or defects early in the production process, preventing costly errors and ensuring the final product's quality.

Tolerance Verification: Enables the verification of tolerances specified in design drawings. Manufacturers can ensure that parts and components meet the required tolerances for proper fit, functionality, and compliance with industry standards.

Reverse Engineering: 3D measuring facilitates reverse engineering by capturing the exact dimensions and geometry of existing objects. This is valuable for recreating components, updating designs, or understanding the structure of complex objects.

Efficiency in Design and Manufacturing: Accurate 3D measurements streamline the design and manufacturing processes. Engineers can make informed decisions based on precise measurements, leading to better-designed products and more efficient production workflows.

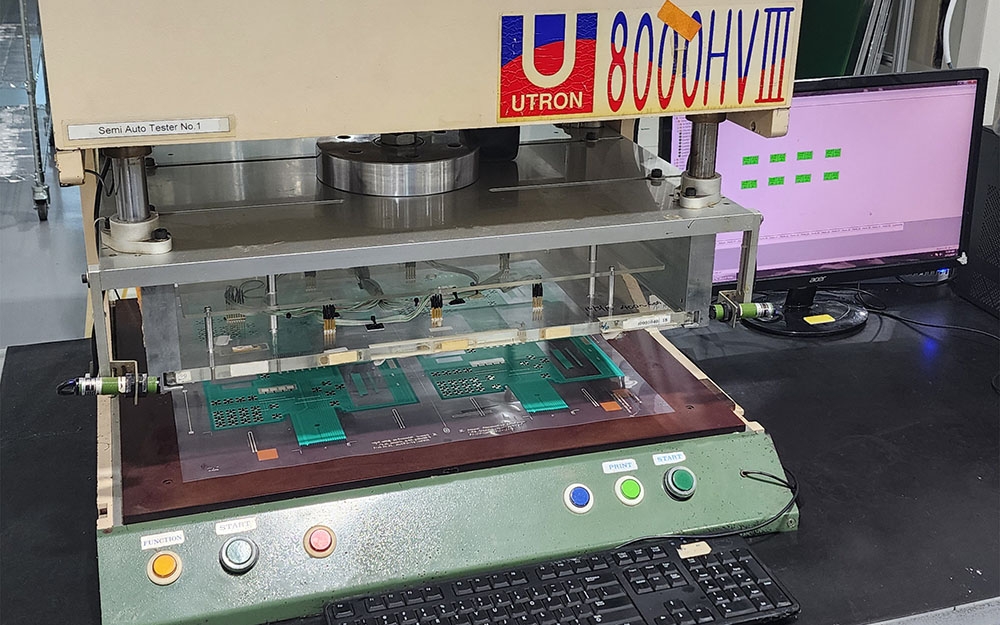

Automation and Speed: Automated 3D measuring systems, such as robotic CMMs, can perform measurements rapidly and with high repeatability. This is particularly advantageous in high-volume manufacturing environments.